From money-draining to money-making

ALLU products make your work faster, safer, and more profitable.

How? With ALLU, you save on transport costs and buying extra equipment. You can even create value by re-using the on-site materials. Finish jobs much faster with improved efficiency.

ALLU works in any industry.

Why ALLU?

1. Proven solutions with decades of expertise: For 40 years, our products have led the market, driven by an innovative approach and a proven track record.

2. Rapid return on investment: Our solutions quickly pay for themselves. You can do everything on-site and avoid material transportation costs.

3. Unmatched Nordic quality: Engineered in Finland, our products are high-quality, durable, and perform exceptionally well.

4. Global technical support: No matter where you are, our global support network is always ready to help, ensuring your operations run smoothly.

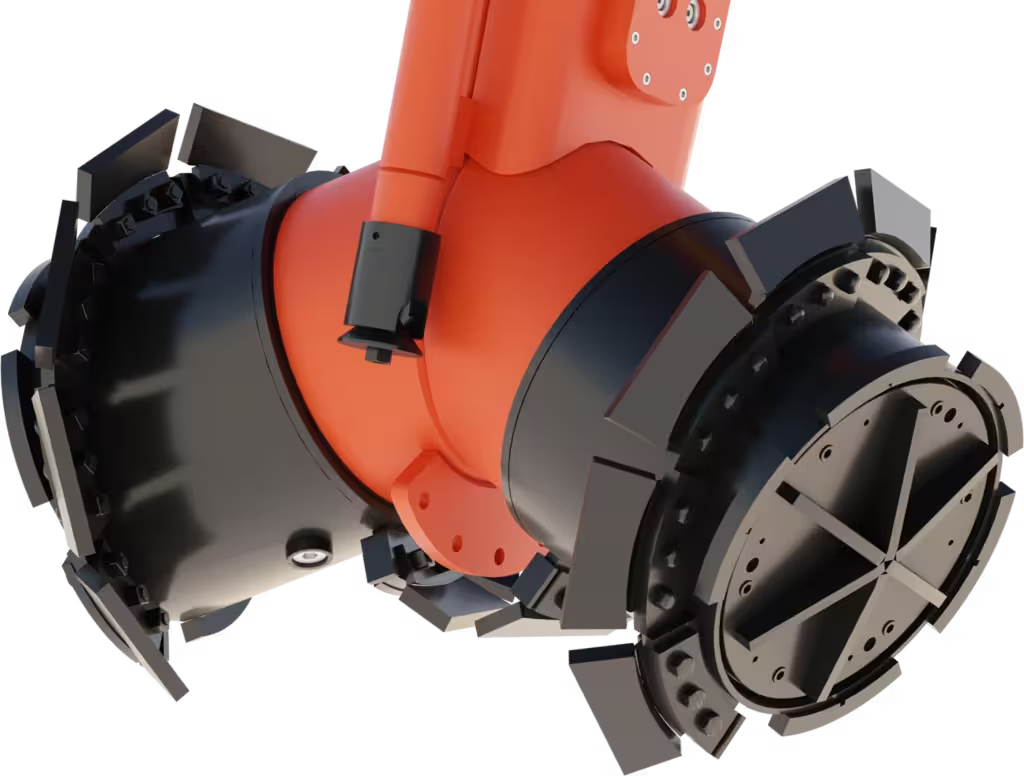

5. Easy integration with versatile attachments: Our products are compatible with most excavators, wheel loaders, skid steers, backhoe loaders and tractors enhancing their functionality.

6. Consistent high-quality outcomes: With ALLU products you get consistent results in your material handling operations ensuring your work quality.

40 Years of Expertise at Your Service

ALLU is a family business that designs and manufactures screening and crushing buckets for the processing, separation, sorting, mixing, and crushing of materials. Typical applications include soil and waste recycling, the treatment of contaminated soil, and the transformation of waste into usable materials.

For four decades, ALLU has provided innovative solutions and expertise in the field of material handling. With a strong commitment to customer satisfaction and continuous improvement, ALLU has established itself as a reliable partner in various industries worldwide. Our headquarters are in Finland, and we operate globally with over 100 local dealers in more than 30 countries.

ALLU Products

The ALLU screening bucket is designed to screen and separate a wide range of materials, including soil, sand, gravel, compost, demolition waste, and biomass.

Contact Us

Our customer service team is happy to answer your queries or arrange a demo. Our global team is on hand to offer all the help you need, we’re just a phone call or email away.

Contact Us

Our customer service team is happy to answer your queries. ALLU global team is on hand to offer all the help you need.